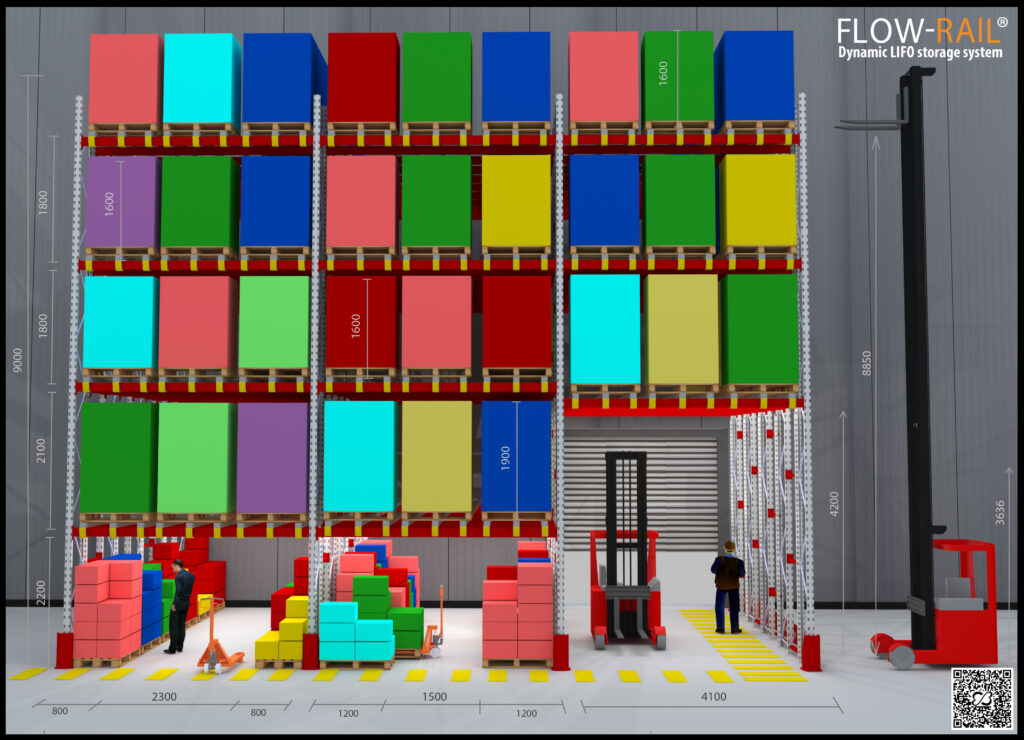

FLOW RAIL®

Optimize time,

space

and safety

What is it?

How does it work?

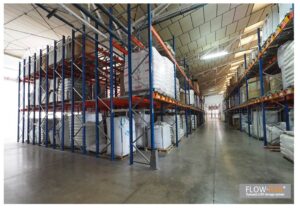

It is possible to start from an existing drive-in or a structure yet to be created.

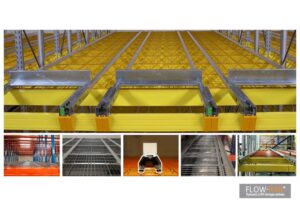

By using toothed chain mechanisms, whose elements slide on rolling bearings, the FLOW RAIL® system ensures the movement of the individual loading and unloading units in the access corridors without the forklift entering the shelving.

The system does not need its own motor as it utilizes the kinetic force generated by the chains placed on the system guides.

See how it works:

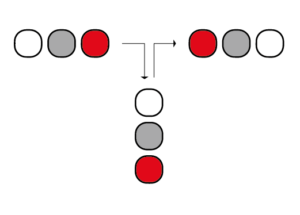

FLOW-RAIL® is organized according to the LIFO logic (last in, first out), minimizing the risk of damaging goods and structures and thus ensuring maximum safety for the operators.

To whom it is suitable?

Who sells to

large retailers

medium / large

sized companies

Cold Rooms

Technical features

The rail and chain assembly measures only 91 mm in height.

It is Extremely resistant, works both indoors and

outdoors at low temperatures (down to -27 ° C).

The toothed chains are made in Spain with the

best components and quality standards.

It can be used for channels from 3 to 12 pallet places in depth

(800 mm / pallet in depth).

As maintenance requires simple cleaning every six / twelve months.

fama & co. srl soc. unipersonale

Via Puccini 4/4 – 48022 LUGO (RA)

ITALY

C.F / P.IVA 01913551204

tampieri@famaeco.com

+39 0545/22489

adhering to: