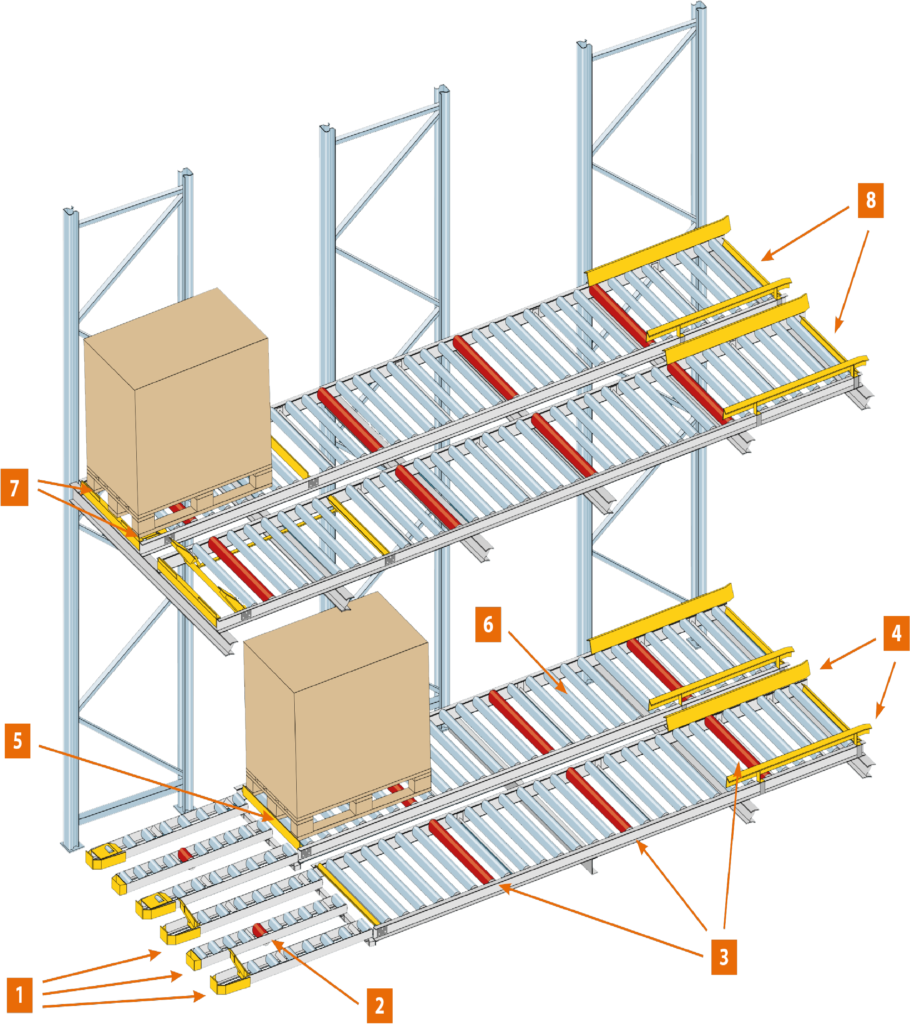

Gravity Roller Conveyors

Designed to be applied to any shelving

What is it?

A series of rollers is supported by a load-bearing structure,

suitable for moving the packages by means of thrust or the force of gravity.

How does it work?

The system consists of a succession of cylindrical rollers positioned on a slope of 4%, which are activated by thrust or under the effect of gravity.

They are the most economical and optimal solution for

LIFO and FIFO management of goods.

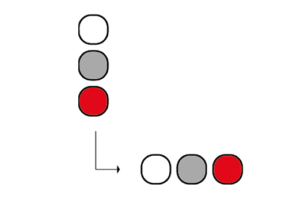

Lifo

Last In First Out

MINIMUM CAPACITY 200 KG MAXIMUM 1200kg

SHORT TUNNELS (ABOUT 12 PALLETS)

Fifo

First In First Out

MINIMUM CAPACITY 200 KG MAXIMUM 1200kg

LONGER TUNNELS (ABOUT 20 PALLETS)

Applications

Picking takes place directly from pallets, which is more ergonomic and accessible

thanks to the excellent sliding characteristics of the rollers.

They can also be used with rotating pallets.

The 3-track design eliminates roll deflection increasing load capacity

and reducing malfunctions

(Roller center distance T = 52mm).

If required, the separator can be equipped with a foot release and empty pallets

can be removed without pressing the full channel.

Technical Features

- Capacity of each roller up to kg. 160 (diam.50 mm, width 400 mm. Galvanized)

- Possibility of using light roller conveyors and plastic rollers together

- Speed slowdown at the end of aisle by clips or braking rollers

- Withdrawal of single pieces or whole cases

- Channel separation using higher side profiles

- Roller conveyors inserted in an existing pallet holder structure

- Heavy duty frames

fama & co. srl soc. unipersonale

Via Puccini 4/4 – 48022 LUGO (RA)

ITALY

C.F / P.IVA 01913551204

tampieri@famaeco.com

+39 0545/22489

adhering to: